Load swapping

Load swapping or flexible loading refers to altering the load sequence of containers to mitigate the late arrival of an AGV at the QC.

In addition to the load swapping (or flexible loading) option that is supported in XPS, PR-TT supports a similarly-named rail load swapping option. For more information, see Swapping rail loads in Navis N4: Equipment Control Administrator and User Guide.

Load swapping can be enabled for an entire work queue or for specific work instructions (WI):

Load swapping is triggered when the AHT with the next container in sequence is late. The AHT ECS is responsible for adhering to or swapping the load sequence.

The pre-requisites for load swapping are:

-

Both WI belong to the same work queue.

-

Neither WI is COMPLETE, or PUT_COMPLETE; PUT_UNDERWAY is one more disallowed WI move stage in case of ECS-requested swaps.

-

Both WIs are planned to the vessel.

-

Both WIs have the same stow factor.

-

Both containers have the same door direction.

-

Both containers weights are within the same tolerance (N4 settings INVCORE_FEAT001 (on page 1) and INVCORE_FEAT002).

-

The AGV ECS supports load swapping.

-

The AGV ECS is aware of the Stow Factors.

-

The container is not hazardous.

Note: As of 3.8.34, there is no validation for requiring tandem WIs for tandem swaps when the load swap is initiated by the ECS.

When the AGV with the next container in sequence is late and flexible loading is enabled, N4 and ECS perform the following steps to achieve flexible loading:

-

The AGV ECS evaluates and selects a container waiting at the PB that can be loaded in the position of the original container.

-

The AGV ECS instructs the AGV with the swapped container to come to the QC.

-

The QC lifts the container.

-

N4 detects the swap and updates the WI and the stowage information to reflect the swap.

What does next container in sequence mean?

If the next container to arrive at the QC is not the expected container – based on Work Queue sequence number – that does not mean it is automatically eligible for load swapping. Containers can only be swapped with the next container in sequence.

Next in sequence means the container currently at the top of the work queue that has not been completed, as planned for that load work queue, and displayed in XPS.

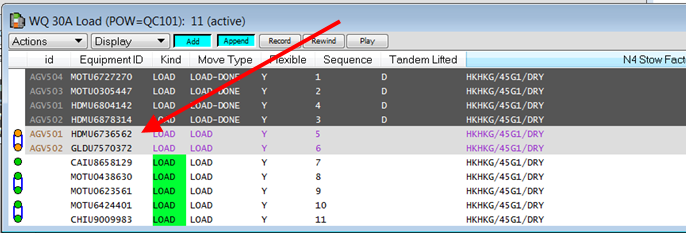

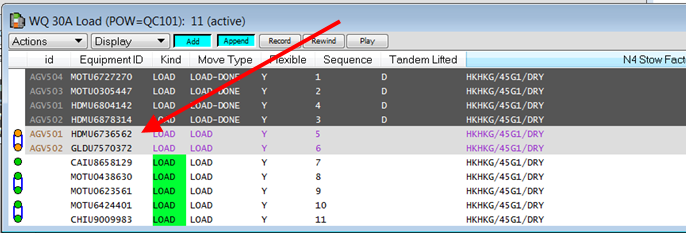

In this screenshot container HDMU6736562 (Sequence #5) is the next container in sequence, as the moves for the containers above it are complete. If a different container arrives next at the QC and it matches the attributes of HDMU676562 it can be swapped. But if a different container that arrives next does not have matching attributes, it cannot be swapped and it cannot go down the list of containers until it does find one it matches with.

For example, using only the stowfactor attribute, the swappability with container A would be as follows:

In this example, only if an AGV arrived at the QC carrying container C or F would a swap with A occur. If container D or E arrived they would not swap with container B just because it was ahead of them in sequence. Load swapping only checks the next container in sequence, which is container A.

Monitoring load swaps in N4 using service events

A service event is displayed in N4, when a load swap fails and when a load swap completes successfully.

They can be viewed from : VESSEL_LOAD_SWAP_NOT_ALLOWED and VESSEL_LOAD_SWAP.

These service events will display details including, but not limited to:

-

: which QC the failed load swap occurred at

-

: the container that could not be swapped

-

: this field is used to provide info on why the swap failed and which containers were being considered for the swap. For example in the following the stow factors did not match (RFR v 8’6):

"Stow Factor Mismatch. Unit UFV[8146:MOAU02321:ACTIVE:FCY111] has a Stow Factor of SGSIN/20’/RFR and Unit UFV[8145:NCCU51423:ACTIVE:FCY111] has a Stow Factor of SGSIN/20’/8’6"

The Notes field example above is from a Not Allowed service event.

This functionality is enabled by default, but you can disable it if you do not need the service events.

Empty containers and Projected Port of Discharge

Empty containers are different than standard containers containing goods. When they are part of a load swap, it is not enough to only swap the sequence number and position, the Projected Port of Discharge (POD) is also swapped.

You can see the POD in N4 by going to and adding the column.

Allow Flexible Loading option in the Planning

Allow Flexible Loading option in the Planning  Maintain Queues

Maintain Queues  Maintain Work Queues window

Maintain Work Queues window  WQ <WQ_NAME> window.

WQ <WQ_NAME> window. Allow Flexible Loading option in the Vessel

Allow Flexible Loading option in the Vessel  Crane Work List

Crane Work List  Crane Work List window.

Crane Work List window.