for a CHE. In manual dispatch mode, you dispatch work instructions one at a time.

for a CHE. In manual dispatch mode, you dispatch work instructions one at a time.Manual dispatching is the dispatch mode available with standard Equipment Control. To dispatch manually, you select a work instruction and click the Dispatch Command Button  for a CHE. In manual dispatch mode, you dispatch work instructions one at a time.

for a CHE. In manual dispatch mode, you dispatch work instructions one at a time.

You can assign several work instructions manually to a CHE at one time. In this "semi-automatic" mode, the first container is dispatched, and Equipment Control automatically dispatches the others as the operator completes each job. On completion of the manual job, Equipment Control sends an XMLRDT message to the CHE to automatically reset its state to idle.

Prerequisites

The CHE operator cannot be performing a manual rehandle. An error message appears preventing the dispatch until that move is completed. Display the Dispatch State attribute in the Pools & Equipment view to monitor the CHE. When the value is 'Rehandling', the system prevents you from dispatching to that CHE.

To dispatch one work instruction manually:

Select Control  Points of Work.

Points of Work.

In the Points of Work window, click a POW to highlight it.

Select Actions  Set Dispatch Mode, and choose manual from the menu.

Set Dispatch Mode, and choose manual from the menu.

Dispatch mode menu options vary depending on Equipment Control configuration at your site.

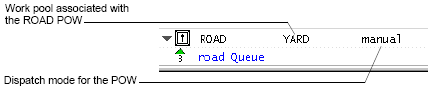

The dispatch mode changes to manual in the POW list.

Double-click a work queue for the POW to open it.

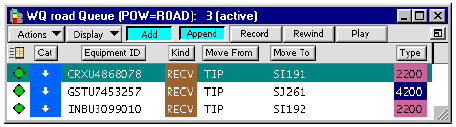

Click a work instruction to highlight it.

In the work queue window, you can display the attribute, Swappable Delivery (in the Handling submenu), to see whether a work instruction is swappable. This is a True or False value. Unless a work instruction is for a delivery request from the gate for a generic empty, this field shows a value of FALSE. In container windows, the field is only visible if the container has an associated work instruction.

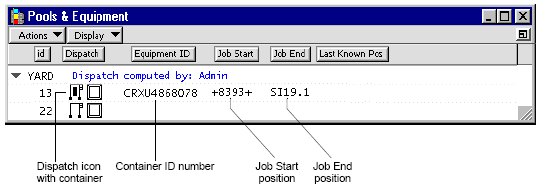

In the Pools & Equipment window (Control  Pools & Equipment), open the work pool associated with the POW. (In this example, the YARD pool).

Pools & Equipment), open the work pool associated with the POW. (In this example, the YARD pool).

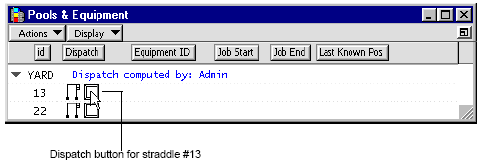

With the work instruction in the Work Queue window still highlighted, click the Dispatch Command Button for a CHE. The job is dispatched to the CHE.

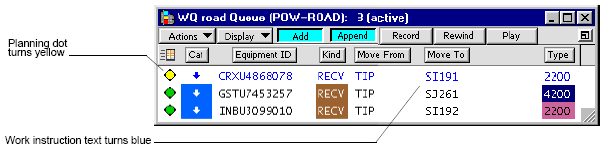

In the Work Queue window, the work instruction’s planning dot changes from green to yellow, and the text turns blue.

In the Pools & Equipment window, the container ID appears in the Equipment ID field for the CHE. A container appears on the CHE Dispatch icon. The Job Start (current position) and Job End (planned position) appears for the CHE. In this example, the move is a receival. The + symbol on either side of the Job Start position indicates that the container is on an external truck.

The operator receives a job message.

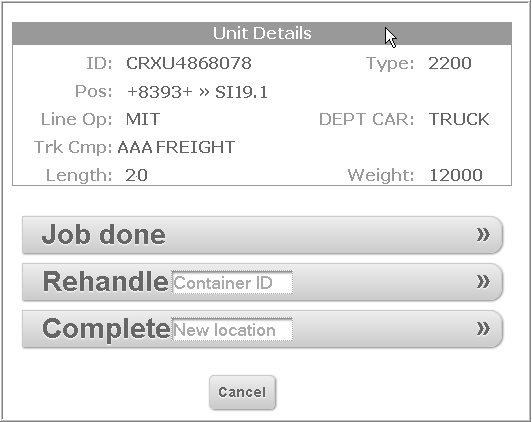

The operator responds to the dispatched job by doing one of the following in the VMT screen.

Places the container in the planned position, and tapping on the Job done button.

Reports a rehandle by entering ID number for the rehandled container in the Rehandle button field, and then tapping the Rehandle button.

Reports a re-route (different set position) for the target container by entering new position for the target container in the Complete button, and then tapping the Complete button.

Cancels the job, by tapping the Cancel button.

Equipment Control updates operator actions immediately, according to the VMT input. Changes in CHE dispatch state, container positions, and productivity appear in the Pools & Equipment window, the work instruction, and in numerous XPS views, lists, and reports.

For details about what to look for in each of these screens, see Monitor job progress (on page 1).