Prerequisites

If you want XPS to auto dispatch dual-cycled containers to the same truck, XPS setting DCTRKM must be set to Y.

To load a vessel efficiently, you can use Equipment Control with Truck Control to double‑cycle (also known as dual-cycle) work instructions.

If you are using Advanced Vessel Planning and PrimeRoute for Terminal Tractors, double-cycling is configured differently. See Navis N4 XPS Advanced Vessel Planning and Control for details.

Double‑cycling has two advantages:

Trucks carry containers both to and from the vessel.

Quay cranes carry a container both to and from the quay. This results in a productivity gain of several moves an hour.

Before attempting to double cycle, you should have a thorough understanding of the single‑cycle vessel load and discharge processes described in Vessel load of two 20' containers from an RTG zone (on page 1) and Vessel load from an RTG zone using Truck Control (on page 1).

Set up work queues for double-cycling

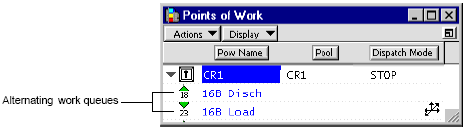

You set up a double‑cycle operation just as you would a single‑cycle discharge or load operation except that you alternate discharge and load queues for each bay for POWs in the Points of Work window, as shown.

For more information, see Set the cycle mode.

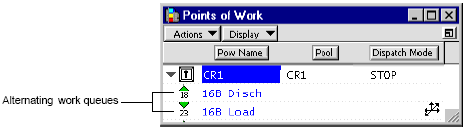

When you alternate discharge and load work queues for a bay and set the POW to double cycle, Equipment Control dispatches a work instruction first from the discharge queue, then the load queue. The alternating discharge/load sequence begins when at least one stack has been completely discharged from a vessel bay so that empty slots exist for load containers.

Vessel discharge and load to RTG blocks

This example describes a vessel discharge and load from an RTG block using Equipment Control with Truck Control.

Double-cycling can be set up differently if your site uses Advanced Vessel Planning and PrimeRoute for Terminal Tractors for vessel loading and discharge. See Link work queues for double cycling in Navis N4 XPS Advanced Vessel Planning and Control for information.

In a road queue, for dual moves carried out by an external truck, when you enable the Equipment Control settings ROADTL and ROADV1, Equipment Control automatically marks the receival jobs prior to the delivery jobs.

The table summarizes the job steps, indicating who performs each step and the dispatch state of the work instruction (WI).

Steps for Vessel Discharge and Load with Truck Control

|

Job Steps for Double-cycle vessel Discharge and Load with Truck Control |

Who Can Perform |

WI Dispatch State |

|---|---|---|

|

1. Perform single-cycle vessel discharge as described in Single container RTG vessel load with Truck Control (on page 1) until one or more stacks in a vessel bay are empty. |

various |

-- |

|

2. Switch the POW from single to double-cycling. |

dispatcher |

-- |

|

3. Sort the POW window to display the jobs in discharge/load tandem. The POW window displays all of the discharge jobs and then all of the load jobs, unless you make this change. |

dispatcher |

-- |

|

4. Assign a load back to each truck after a discharge is completed to the yard. The RTG operator receives a job list message for the load move. The truck receives a job message to go to the yard location for the load. |

Equipment Control |

assigned |

|

5. Dispatch the load to the truck. The truck receives a job message to take the container to the crane. |

operator |

dispatched |

|

6. Confirm the load move using the Hatch Clerk program. The truck receives a job message to wait for another discharge. |

hatch clerk |

completed |

|

7. When the last container is discharged and only loads remain, switch back to single‑cycle mode and complete the load moves as described in Single container RTG vessel load with Truck Control (on page 1). |

dispatcher |

-- |

To perform double-cycled vessel discharge and load:

When at least one stack from a vessel bay is discharged, the dispatcher or hatch clerk switches the POW to double‑cycling mode.

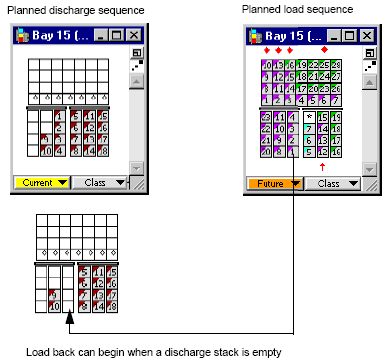

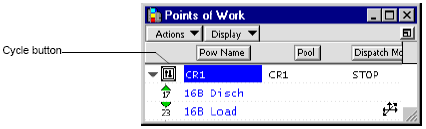

In the Points of Work window, the dispatcher switches to the dual mode. There are two ways to do this:

-- Click the cycle button  to the left of POW Name, and then select Dual from the dialog.

to the left of POW Name, and then select Dual from the dialog.

-- Highlight the POW, and then select Actions  Set Cycle Mode

Set Cycle Mode  Dual

Dual

The cycle button changes to indicate double-cycle mode.

If you stopped dispatch at the POW to change the mode, set the Dispatch Mode to Trucks to start work again.

To display the job list for dual-cycling:

In the Point of Work window, select Display and ensure Sort By Sequence is not checked.

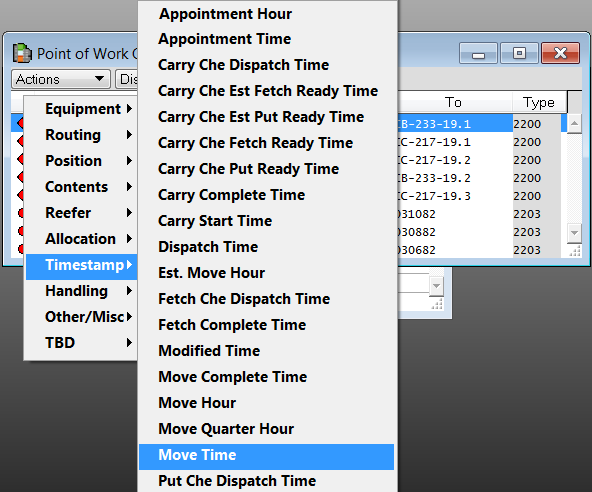

Select Timestamp  Move Time, to add it as a sortable column.

Move Time, to add it as a sortable column.

Sort the list by Move Time.

The jobs are now listed in pairs of discharges and loads, which accurately represents the order in which the jobs should be completed.

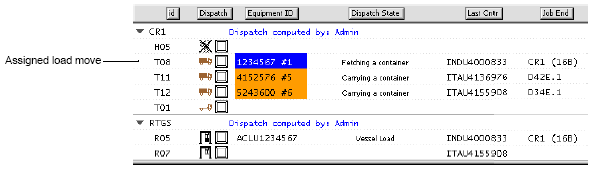

When the first double-cycled discharge is completed to the yard, Equipment Control assigns the load‑back instruction to the truck.

In the Pools & Equipment window, the container's Equipment ID number appears on a blue background. The truck's Dispatch State is ‘Fetching a container.’

The load back instruction appears on the VMT of the assigned truck.

The truck goes to the assigned yard row to pick up the load container.

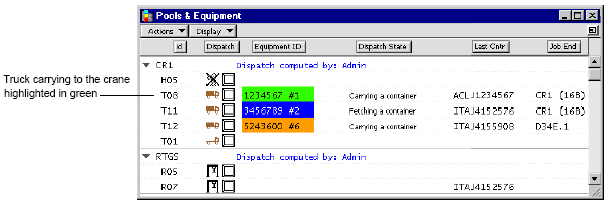

An operator dispatches a load container to the truck.

In the Pools & Equipment window, the container’s Equipment ID number displays on a green background. The truck's Dispatch State is ‘Carrying a container.’

The truck receives a load message on the VMT.

The truck takes its container to the crane.

The hatch clerk, using the Hatch Clerk application, completes the container move to the vessel.

After the container is completed to the vessel, the truck receives a message instructing it to wait for a discharge.

Using Hatch Clerk, the hatch clerk dispatches a discharge container to the truck.

In the Pools & Equipment window, the container’s Equipment ID number displays on an orange background.

The truck receives a job message to carry the container to its planned yard position, and the RTG receives an updated job list.

Double‑cycling continues until there are no longer loads and discharges for the bay.

Turn off double‑cycling when the last container is discharged from a bay. You can then continue loading the vessel in single‑cycle mode.