Barge operations are a type of container terminal operation where small ships or platforms without auto- propulsion (barges) are used. The barges are used normally to transfer containers between container terminals of the same port or for inland shipping.

In this type of operation, discharges and loads usually do not have a specific plan with the positions on the barge, even the exact ship geometry of the barge is not defined in the TOS. This is known as 'unconfigured' barge operations. The regular type operation when containers have a slot associated and the exact ship geometry is known as 'configured'.

In the case of discharges, they are lifted by the BC (barge crane) operators in the order they are in vessel and the discharge event is registered after the container is identified, after this the container is sent to the yard.

In the case of loads, they are not planned to a specific slot in a specific bay, they are plan to the barge in general, the work instructions are sent following the planned sequence to the crane and the BC operator loads it to the next available slot.

Barge Functionality in XPS

XPS supports the barge operations totally unconfigured, i.e. all discharge and load work instructions are in a general discharge or load queue respectively.

The behavior of the barge operation in XPS is driven by the setting VQ1LDQ.

This setting sets globally if all the barge visits are operated with a single discharge WQ and a single load WQ (VQ1LDQ=Y) or all barge visits are operated as a regular vessel with independent WQs (VQ1LDQ=N). Given that we are interested on that most of the barge visits are worked with single WQs (unconfigured mode) this setting would be configured to Y(es).

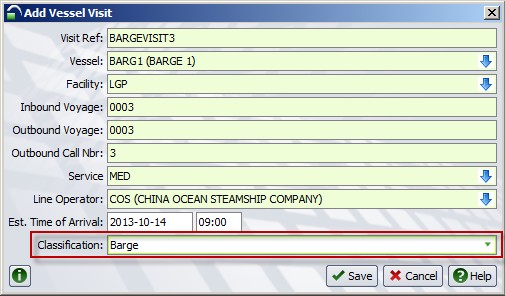

In order to operate a barge, the first step is to create the visit for the barge in N4, the Classification of the visit must be set to Barge.

Once a barge visit is created, it is possible to start planning the operation.

By default, if the parameter VS1LDQ is set to Y(es), discharge and loads work instructions are added to a general discharge or load work queue.

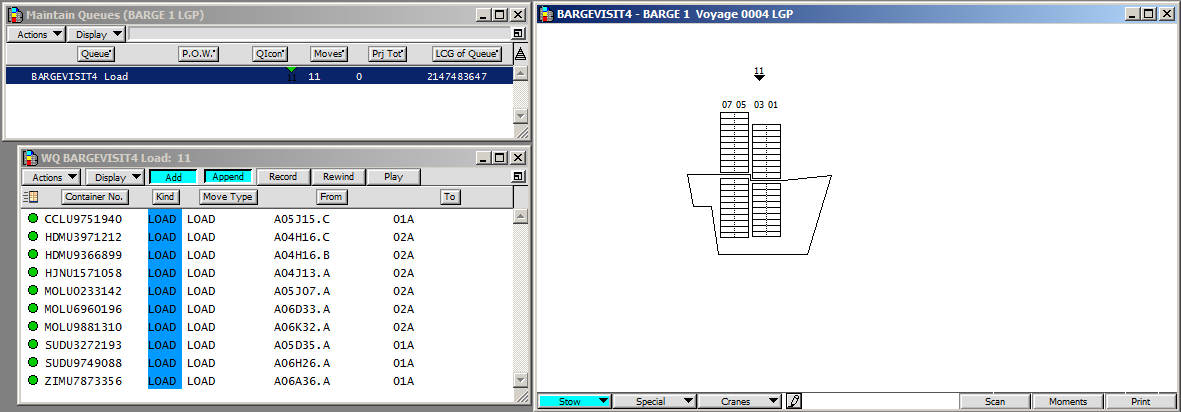

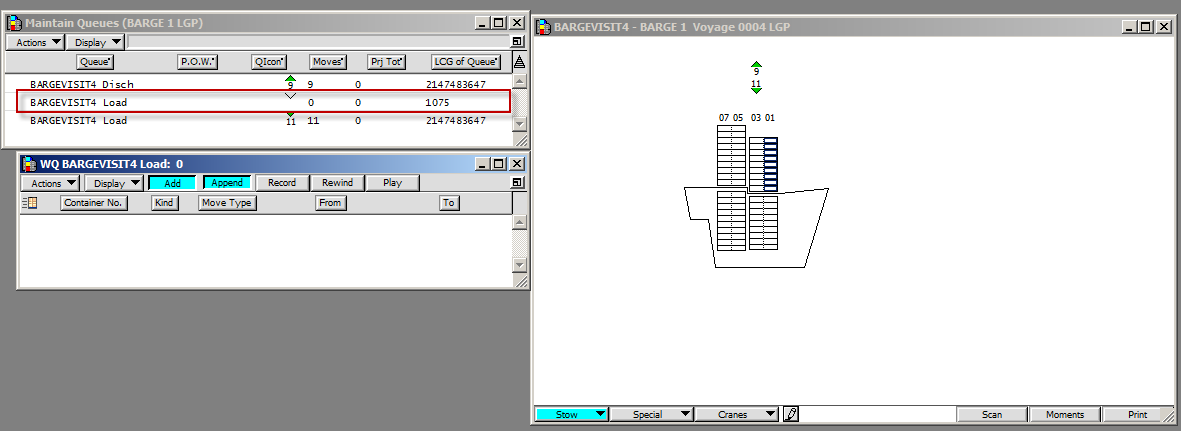

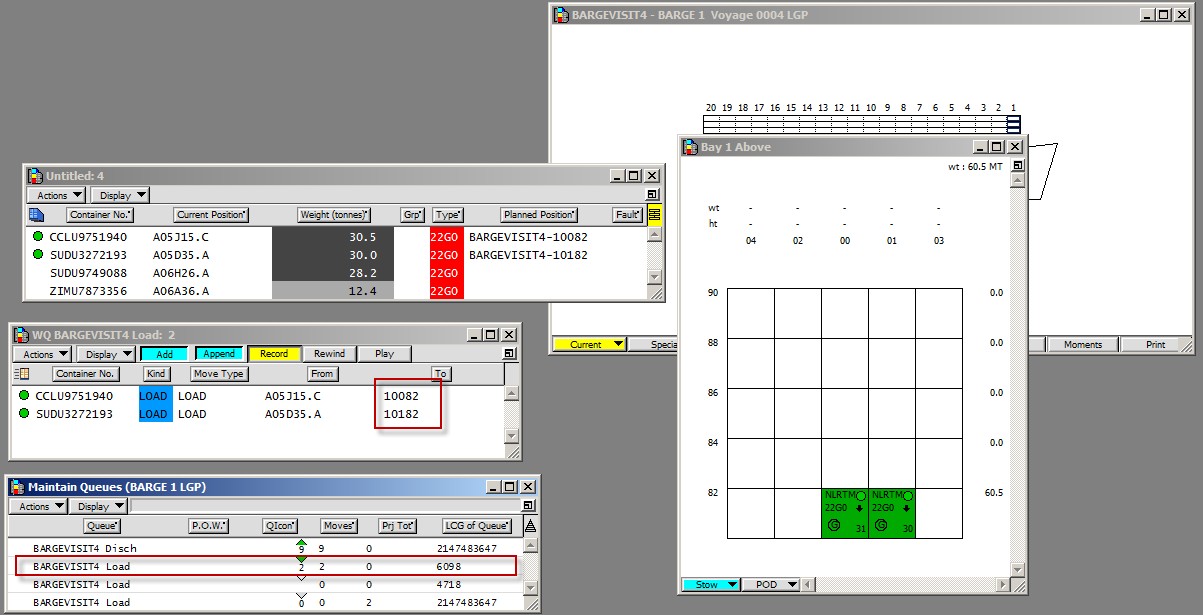

For example, in the case of this barge, we shall plan the load containers with the bucket tool to a particular bay and deck. After planning the containers, the general queue is created.

Please note the LCG value of the new work queue (2147483647), this value is not an actual LCG value of any of the bays of the barge. When this value is associated to a WQ, this work queue shall be unconfigured. So this is an unconfigured load situation.

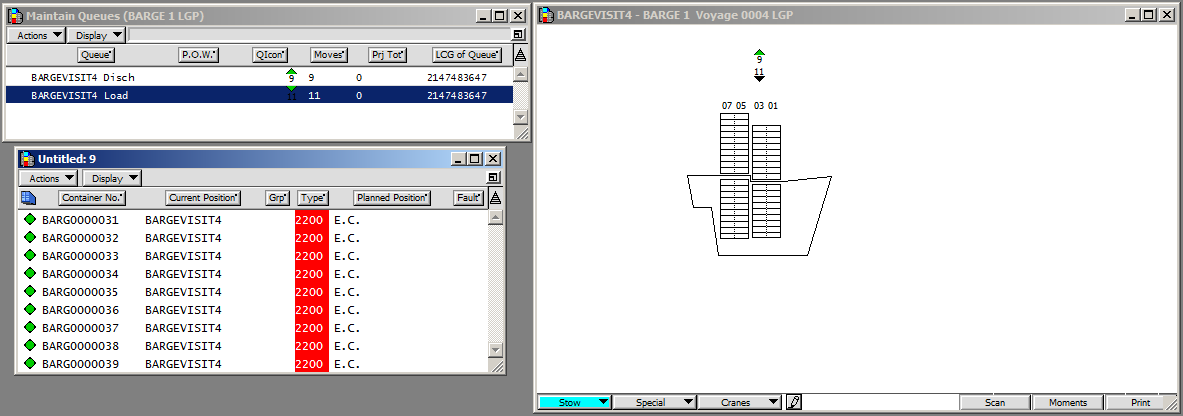

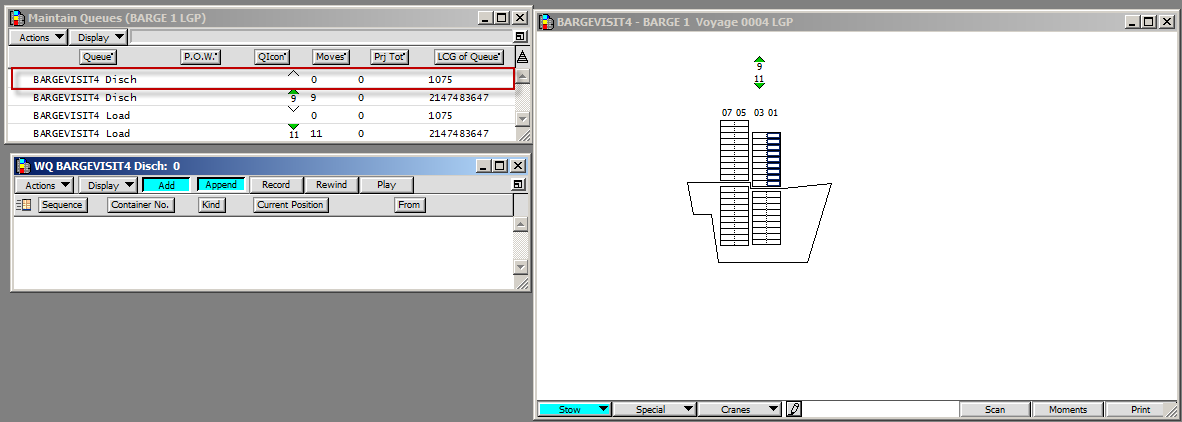

Same situation occurs for discharges after planning them, for example, to E.C., a general work queue is created with the same LCG value:

So this shall be an unconfigured discharge work queue.

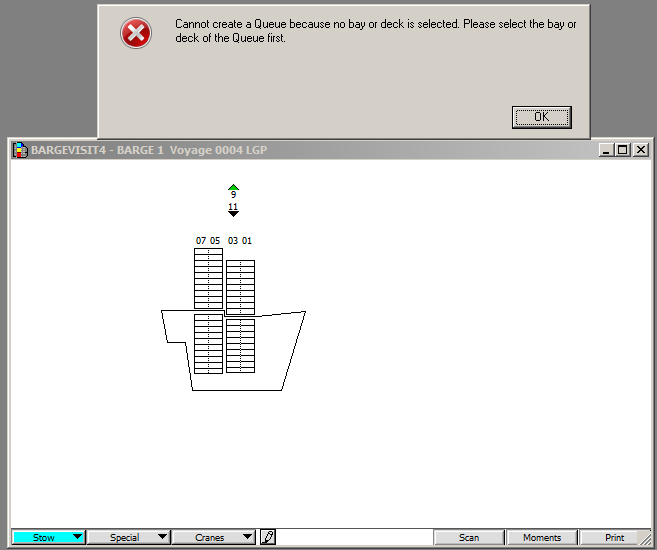

But XPS offers another method to create a vessel load or discharge work queue. This is using the option Special > New Load Queue… (or New discharge Queue…), when we uses this option XPS asks to select a bay and a deck.

So selecting the bay and deck, the work is created.

Although the same is the same to the general one, this work queue has a really important difference, the LCG value has the actual value of the selected bay. So if this value was defined in the ship geometry, i.e. it is known and not estimated.

Same situation occurs with a discharge queue.

So this would be a configured discharge work queue.

After the work queue is created, the work instructions can be appended to it.

Please note that stow positions of the containers do not affect to determine if the work queue is configured or unconfigured. The LCG value of the Work Queue is determining this, so if containers are planned to specific locations on the barge, the uses has to take this into consideration to append the work instruction to the corresponding work queue.

Planning containers from/to specific stow locations

As an example, we will plan a barge to be operated with unconfigured discharge work and configured load work queue.

As a pre-requisite, we will assume that the barge ship geometry has been defined with known LCGs values.

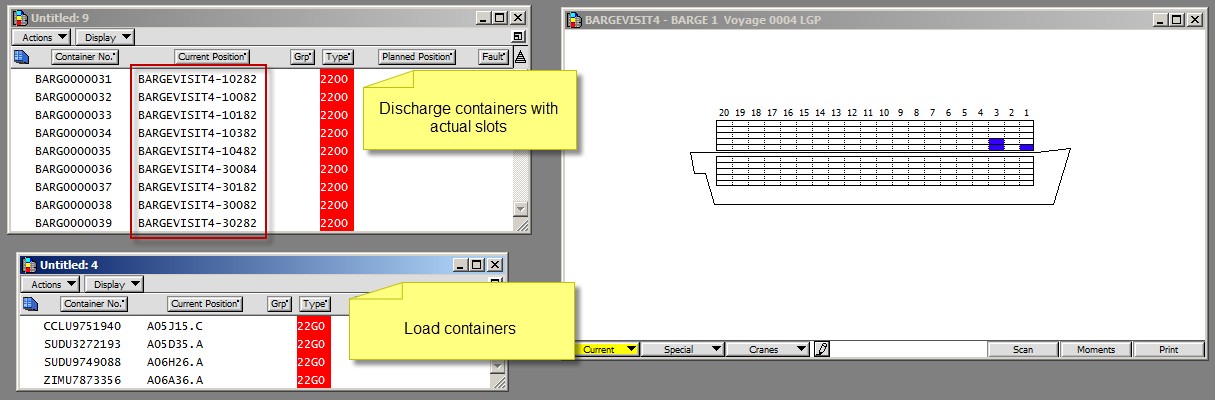

This is the initial situation:

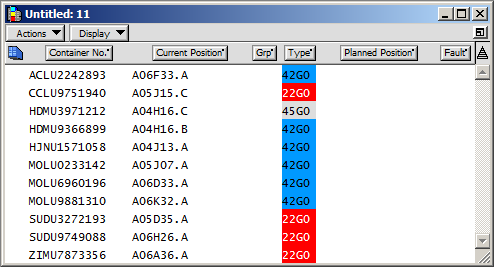

In this example, the discharge containers have actual slots although they will be discharged in unconfigured mode. Load containers shall be planned to actual slots too.

First we plan the discharge to E.C., by selecting all the containers and ‘bucketing’ them to the EC logical block.

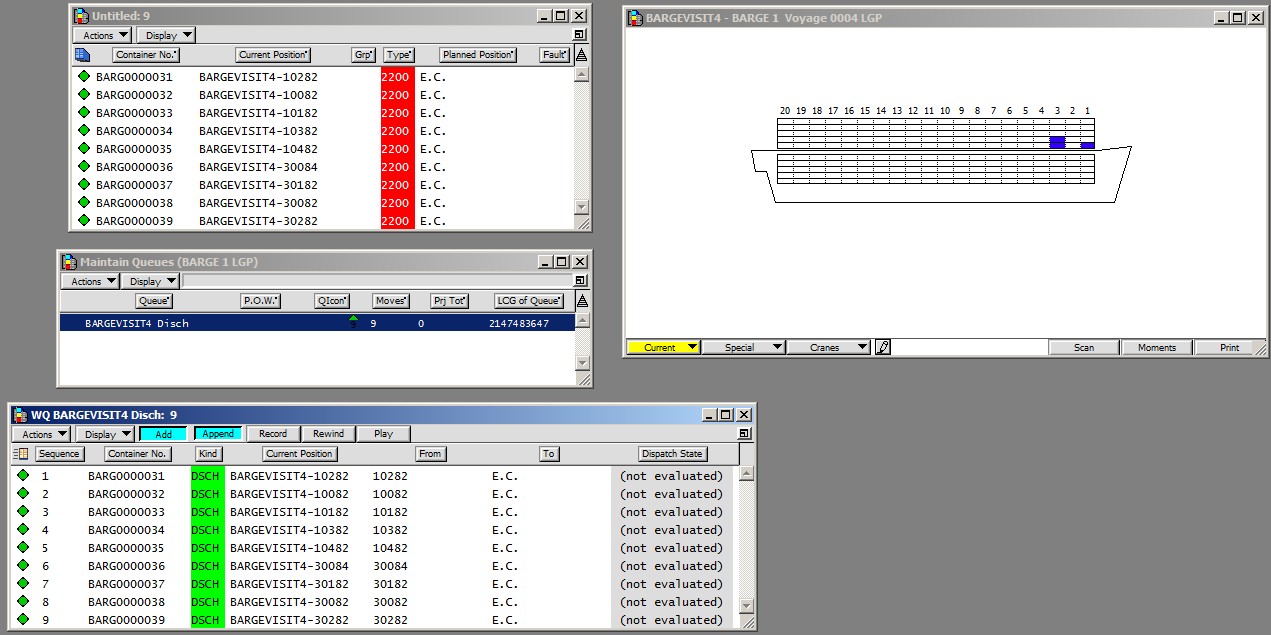

We can observe that a general discharge work queue has been generated with the special LCG value, so this work queue shall be operated as Unconfigured.

After the discharge, we will plan the load. For the steps can be done in different ways: A first possibility is:

Plan the containers to the specific slots.

Work instructions shall be added to the general load queue by SPARCS.

Create the specific work queues.

Append each work instruction to the corresponding WQ. A second possibility is:

Create the specific work queues.

Plan the load containers to the specific slots ‘recording’ the work instructions to the specific work queue.

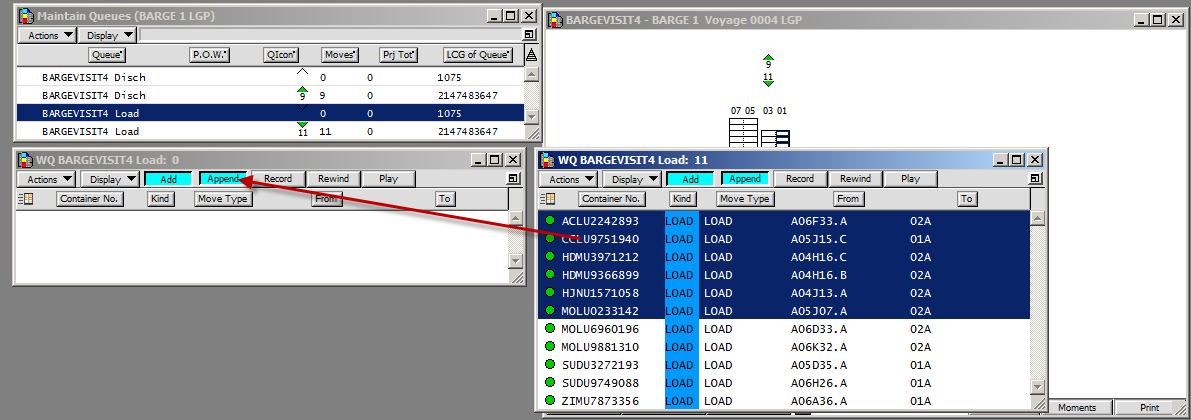

The first option was shown before, in this case we shall use the second possibility.

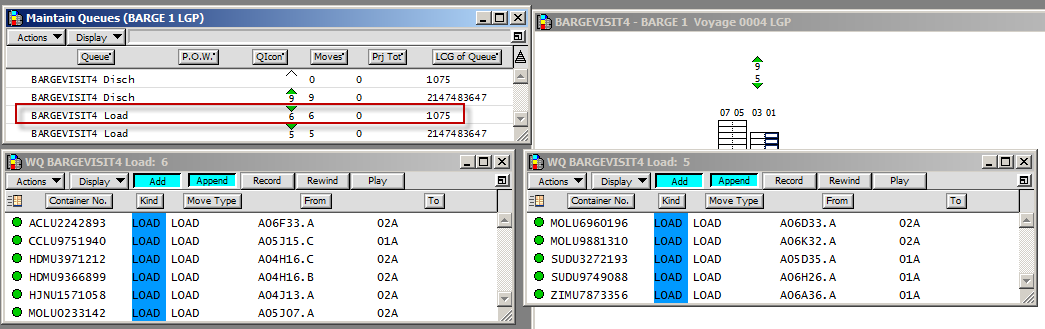

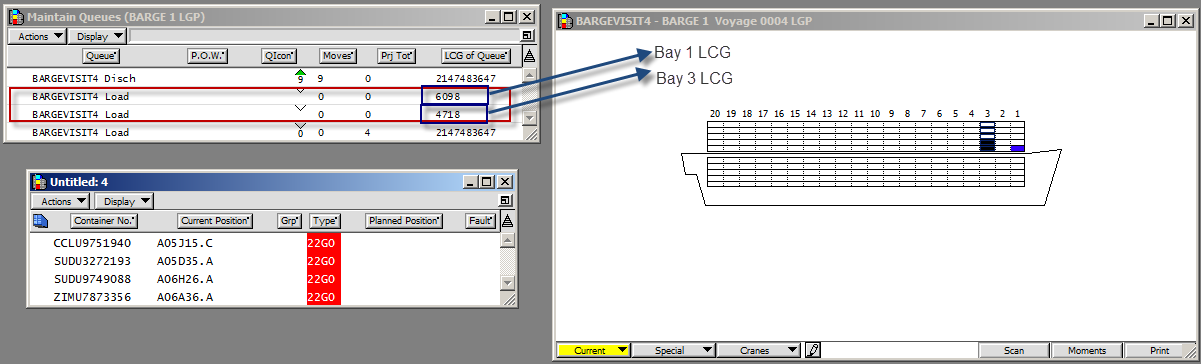

The first step is to create the load work queues (we assume that the projections were already added to the barge). In this case the containers shall be loaded to bay 1 and 3.

The 2 WQs have been created and they contain the LCGs of the particular bays.

Currently all the work queues share the same name, this shall be very confusing for the user so this must be enhanced to contain a name related to the bay and deck and the move kind, e.g. 25A Disch.

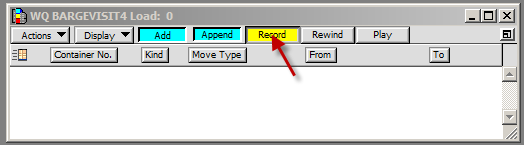

To add the new work instructions to a particular WQ, we shall use the ‘record’ option of the particular WQ.

And then we plan the moves. When the moves are planned, the corresponding work instructions have been added to the WQ with the record option activated.

Please note that the containers have a specific stow position on the vessel and, because the work instructions belongs to a work queue with a specific LCG, this shall be worked in configured mode.

The same process is followed to plan the rest of containers.

With this planning, the discharge will be operated unconfigured and the load will be operated configured.

Separating work queues by container size

All the examples shown above, uses the same work queue for different container lengths, i.e. 20s and 40s are in the same work queue. But it could be possible that independent queues by size are required.

SPARCS N4 supports this possibility making use of the configuration setting WQXLEN. It is important to remark that, as a configuration setting, this setting affects all the vessel operations, i.e. to deepsea,feeder vessels and barge.

This is the behavior of XPS when this parameter is activated.

For unconfigured operations

To illustrate this case we shall use an example, we have these load containers (20s and 40s) to be planned for the barge.

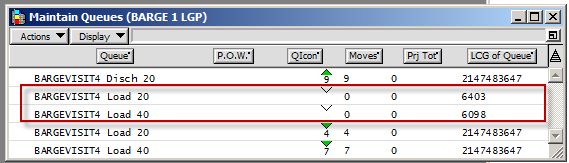

These are the general work queues that the system uses:

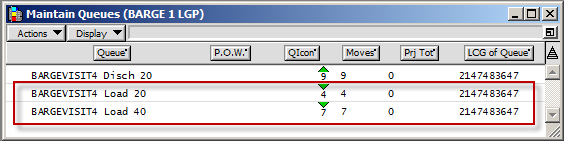

Please note that in this case, XPS creates 2 general work queues, one for each length.

For configured operations

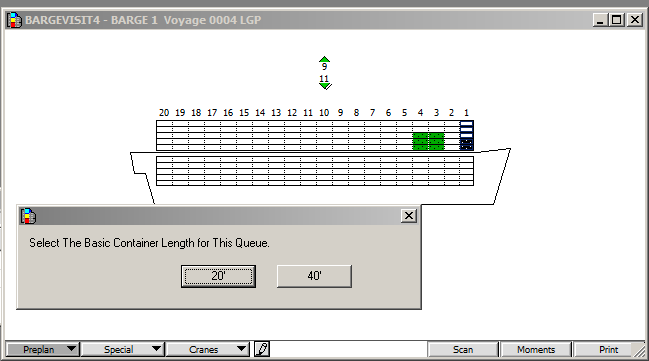

In the case of configured operations, the key is what happens when the configured work queue is created. When WQXLEN is activated, XPS ask for the length of the work queue when it is being created.

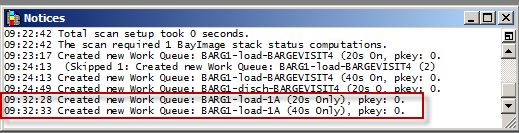

If we create both queues 20 and 40 for the same bay, we shall have 2 different work queues and XPSshall calculate the right LCG for each one.

Please, note that the naming needs to be enhanced but they were created selecting the same bay. Actually this is the output in the notices window:

After the work queues are created, the user shall have to move the work instruction to the correct WQ taking into consideration the size, bay and deck.

Twin case

This functionality takes into consideration the length of the container, so twins are placed by default in the 20s WQ of the fore container. The twined work instructions could be moved to the 40s WQ manually if this is desired.

In This Section