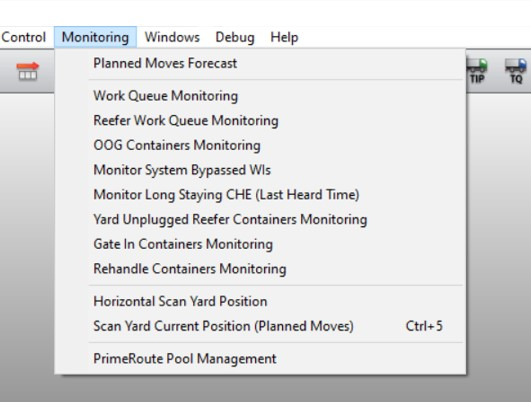

XPS Monitoring menus enable you to monitor specific operational scenarios that can cause delay in completing the moves or impact/disrupt terminal productivity.

Who uses them?

Control room staff, who use XPS to monitor terminal operations.

Why use them?

Monitoring menu let you focus in on specific operational scenarios that can lead to delays. Highlighting specific WIs or CHEs that may have an issue, enables you to immediately address the problem.

Where do you see them?

To access the Monitoring menu, your terminal should have licensed the XPS Monitoring option.

Monitoring menu functionality can be enabled through the following Licenses, setting and privilege:

Licenses: MonitoringMenu and HasASCs license.

XPS Setting: OPTMON

Value: If this setting is set to Y, XPS main menu displays the Monitoring menu with its sub-menus.

Default: N

XPS Privilege:

MONMNU (on page 1)

Description: If you turn on MONMNU for a particular user group, XPS allows only the users of the selected group to access the Monitoring menu.

Default: OFF

How do you use them?

Once you have opened the Monitoring menu, you will have Actions menu and Display menu options available in that window to help complete tasks and customize what you see.

Monitoring sub-menus at a glance:

The following table gives a quick description of the sub-menus in the Monitoring menu:

|

Sub-menus in the Monitoring menu |

Description |

|---|---|

|

Planned Move Forecast (on page 1) |

The Planned Move Forecast list window provides an overview of all the planned yard, gate, and vessel (Inbound/Outbound) moves. This list helps to identify the congestion in the yard and POW areas so that the control room users can coordinate with planners to make the necessary changes to the WI plan. Also, this list is dynamic and provides live gate operations and yard container movements that are dispatched, planned, or currently in progress. |

|

Work Queue Monitoring (on page 1) |

The Work Queue Monitoring list window displays the queues for all the POWs that are not activated for the selected moves. This helps the control room users to identify and activate the work queues that need to be activated ahead of time thereby minimizing the impact on cost and operations. |

|

Reefer Work Queue Monitoring (on page 1) |

The Reefer Work Queue Monitoring list window displays active and inactive WQs for all POWs with live reefers that have not had disconnect requests sent, within the selected number of moves (30 by default). This helps the control room users to ensure that the reefers are disconnected on time thereby avoiding any delay in loading the reefers. |

|

OOG Containers Monitoring (on page 1) |

The OOG Containers Monitoring list window highlights the OOG containers well ahead of their EMT, to provide staff with enough of a warning to minimize the impact on operations. The user can accordingly select the future moves to view the respective OOG WQs for all the POWs. The users in the control room can coordinate with the yard and vessel operators to be ready for the operations thereby avoiding operational delay. |

|

Monitor System Bypassed WIs (on page 1) |

The Monitor System Bypassed WIs list window displays all the containers in system bypassed state including the system bypassed containers in Carry underway state. |

|

Monitor Long Staying CHE (Last Heard Time) (on page 1) |

The Monitor Long Staying CHE list window displays the laden or unladen terminal tractors (TT), straddle carriers (SC), or Automated Guide Vehicles (AGVs) that are in the same job step for a long time. Especially in a terminal with global pool, this window helps to identify the CHEs that are not available for a particular job and helps the control room user to focus on the CHEs with faster turn around time for the jobs. |

|

Yard Unplugged Reefer Containers Monitoring |

The Unplugged Reefers in Yard Monitoring list window helps the yard planners, vessel planners and control room users to identify the unplugged reefers in the yard. This list helps the planners and reefer team members to coordinate with the control room users to plug the reefer units without delay. |

|

Gate In Containers Monitoring (on page 1) |

The Gate In Containers Monitoring list window helps the yard planners, vessel planners, and control room users to monitor the gate movements. This list displays the containers that are to be delivered in or received from the yard and the list of containers that remain in the road queue for a long time. |

|

Horizontal Scan Yard Position (on page 1) |

The Horizontal Scan Yard Position list window displays the multiple containers yard scan position in a horizontal view with a window sizing option (similar to vessel bay scan view) so that planners can perform the job without scrolling the yard Scan window. |

|

Scan Yard Position Current Position (Planned Position) (on page 1) |

The Scan Yard Current Position (Planned Position) list window lists the single or multiple containers yard scan positions in the current time frame so that planners can perform the jobs on time without too many manual operations. |

|

Delayed Load Moves from ASC Block |

The Delayed Load Moves from ASC Block window displays the delayed load containers from the ASC block for an active vessel so that necessary actions can be taken to avoid delay in operations. |

|

Multiple Containers In ASC Slot |

The Multiple Containers In ASC Slot window displays multiple containers in the current and future timeframe in the ASC slot. |

|

Job Planned Away from ASC Split CHE Range |

The Job Planned Away from ASC Split CHE Range window displays containers in parallel ASC transfer zones (TZ), that is where the container’s current position is in the TZ and the planned position is away from the covering ASC. |

|

Rehandle Containers Monitoring |

The Rehandle Containers Monitoring window displays all the rehandle containers for an active working vessel at the berth or an inbound vessel, using the multiple options provided in the Display menu in the Rehandle Containers Monitoring window. |

|

PrimeRoute Pool Management (on page 1) |

PrimeRoute Pool Management functionality is used to identify the discrepancies between Max PMs and Actual PMs in the pool when the dispatch mode is set to PR-TT or PR-SC. This functionality operates in real-time, calculating MAX PMs and CHE within the pool and notifying the dispatcher, controller, or shift manager of any discrepancies within the same window. PrimeRoute Pool Management window displays all pools that are operating in the PrimeRoute mode and indicates the status of Max PMs in comparison to the Actual PMs deployed in each pool. Based on the Max PMs and Actual PMs values, it displays pool management problems for PR-TTs and PR-SCs and provides additional status information such as "Try to reduce MaxPM by X number," "Try to increase MaxPM by X number," "Try to assign X number of TT or SC to pool," or "Well done." |